Responsibility

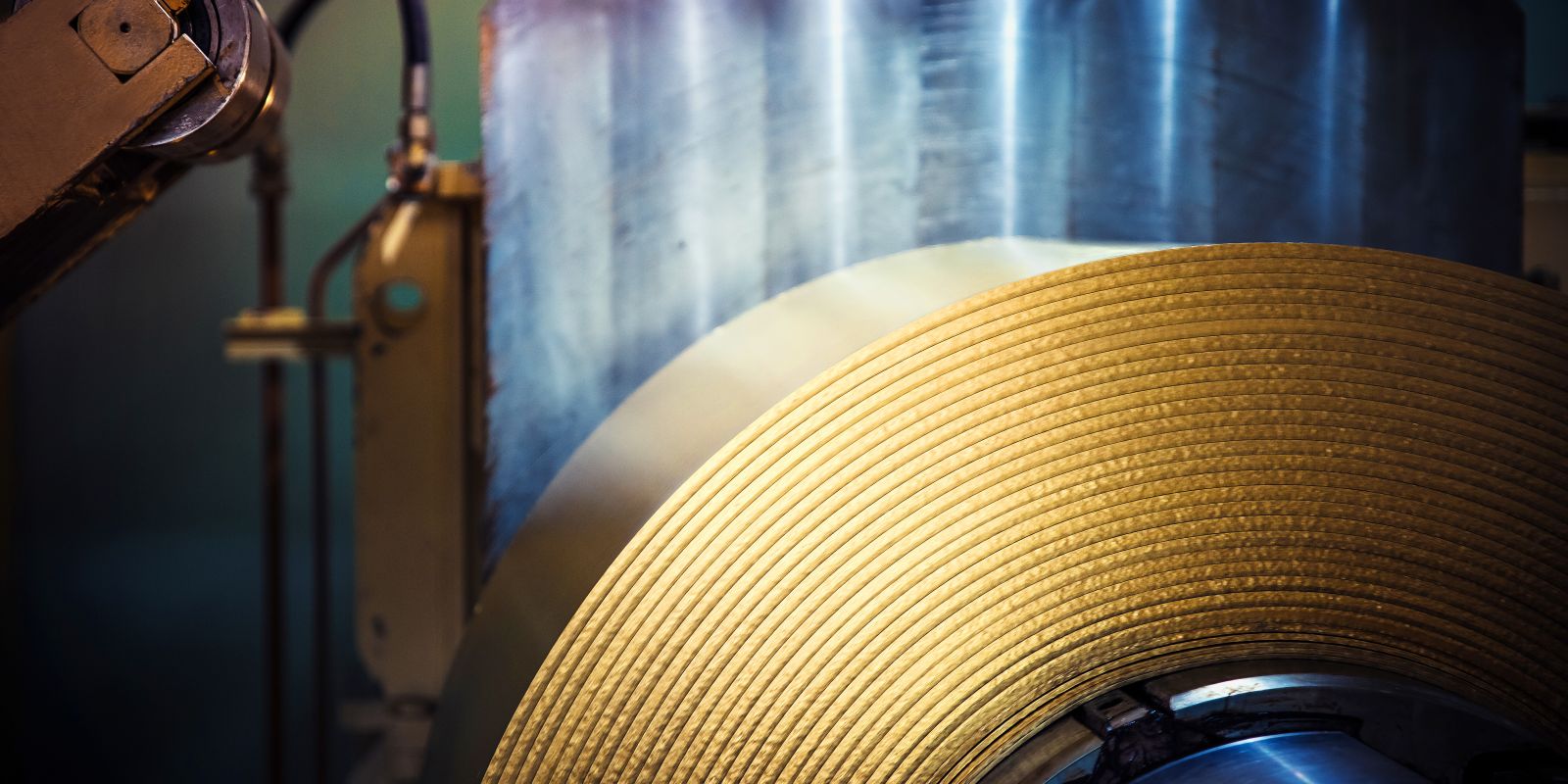

We are one of the world's leading manufacturers of semi-finished copper and copper-alloy products. Our code of conduct sets out the fundamental principles of cooperation with business partners, customers, colleagues, agents, competitors and the public. As our reputation depends upon each and every employee, it is important that they - whatever their position or role - maintain our code of conduct at work.

- Clear customer focus during product and process design.

- Strict compliance with the group-wide company code of conduct.

- "Zero Accident" culture with the provision of a safe and healthy work environment for our colleagues, visitors and contractors.

- Continuous risk assessment relating to operational procedures and future activities.

- Proactive compliance with legal requirements, customer expectations and other standards.

- Implementation and support of the best available techniques and methods to continuously improve our processes.

- Implement strategies to prevent pollution and accidents, to ensure the long-term viability of KME Group.

- Efficient use of materials and energy during the manufacture and provision of our products and services.

- Manufacture products that fulfill the three key requirements of:

- “safety”

- “energy efficiency”

- “recyclability”

- Open dialogue with our neighbors, authorities and any other interested parties.

- Promote a culture where all colleagues share this commitment.

Code of Conduct

This is only a summary of the code of conduct. Click the icon on the right side to download the full code.

Health, safety and environment

Health and safety are very important to us and our goal is to keep improving. Before undertaking new projects and activities, we assess their effects on the health and safety of our employees. We have developed a range of tools that help us to recognize and rectify potential workplace hazards. We minimize the risk of accidents and guarantee compliance with legal requirements, in order to improve overall safety.

This is confirmed by the ISO 45001:2018 certification achieved by both of our Stolberg plant. ISO 45001:2018 is an internationally recognized standard for occupational health and safety management systems. It deals with the following areas:

- The planning of hazard identification, risk assessment and risk control

- Structure and responsibility

- Training, awareness and competence

- Operative management

- Emergency preparedness and response

- Performance measurement, monitoring and improvement

Certificates ISO 14001:2015, ISO 45001:2018

- Header Picture: © fauxels / Pexels